System for investigation of interfacial phenomena of liquid metals in the contact with solids [project 052]

Description

System designed for studies of thermodynamics and kinetics of phase transformation:

|

- Investigation of factors affecting stability and reactivity of materials in different environments

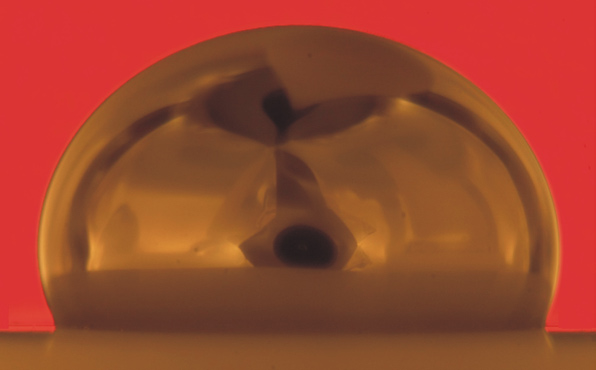

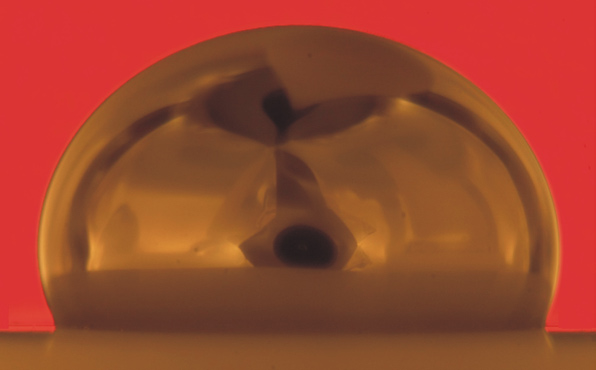

- Studies of high temperature liquid state phenomena (wettability, spreading, infiltration, interfacial reaction)

- Measurements of contact angle, surface tension and density of molten materials at 20-2000°C under vacuum or protective atmosphere using a sessile drop method

- Determination of thermal expansion/shrinkage of liquid and semi-liquid materials during heating/cooling

|

Specification

The system is characterised by the following features:

- Vacuum chamber for first stage sample preparation by preheating in vacuum up to 200°C in order to remove adsorbed gases

- Distribution chamber for sample transfer equipped with dedicated manipulator for samples of different size and various shape

- Auger spectroscopy for surface characterisation of examined materials before and after high temperature studies or special treatment

- Experimental chamber for high temperature studies of materials in solid, semi-solid or molten states, containing an experimental table with rotation and vertical movement, heater and moveable screens and additional windows for observation and recording

- Storage chamber

- Residual gas analyser

|

|

System capabilities:

- Classical sessile drop method, improved sessile drop method (dispensed drop, capillary purification technique)

- Transferred drop (sandwich method, double plates method)

- Pendant drop

- Maximum temperature 2000°C

- Vacuum up to 10-7 hPa or protective atmosphere

- Flowing gas with controlled rate at required level of pressure inside vacuum chamber

- Controlled heating of examined paired materials

- Independent loading system

- Automatic real-time control of chemical composition of atmosphere during tests

- Automatic real-time control of temperatureControl of chemical surface of examined samples before, during and after tests